MASSIVE AIR BARRIER PROJECT AT UCLA COMPLETED WITH CAT 5

2 phases. 5 buildings. 8-10 stories each. ~700,000 sq. ft. of air barrier. 2 1/2 years of construction.

BUILDING ENVELOPE: AIR & WATER BARRIERS

Proven to withstand extreme weather conditions, PROSOCO R-Guard air & water barrier-protected buildings are more durable, resilient and sustainable.

FastFlash Case Study: 10 Years of Proof

In this episode of PROTalks,

we discuss mock-ups and why every project should make them, and lament the reasons why so many don't.

YOUR BUILDING IS MORE THAN

THE SUM OF INDIVIDUAL PARTS.

All components in a wall assembly must work together as a system.

That's why we recommend (as do most building codes) a systems approach to protect your entire building.

Ted Barnekoff, Product Support Specialist

18 years of experience

HELP ME, TED

Air & water barriers support

Success stories

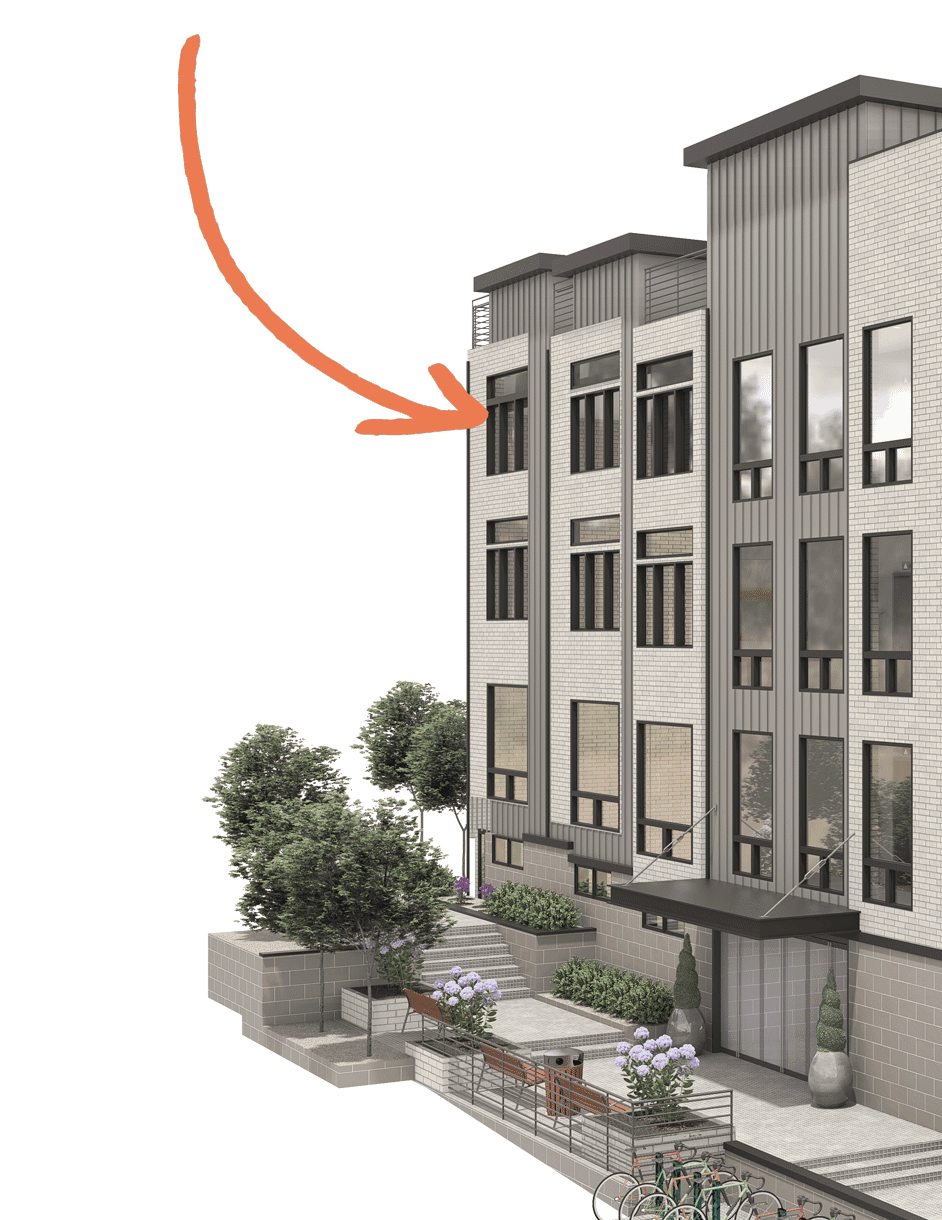

WORLD'S LARGEST PASSIVE HOUSE

That prestigious title – all 330,000 square feet, 276 units and 750 windows of Second + Delaware, was Jonathan Arnold’s vision.

BEACHFRONT HOME vs. MOTHER NATURE

When someone spends this much on a home, they want to protect it from the elements.

REPLACE WINDOWS THE RIGHT WAY

Our friend Matt Risinger has created this really helpful video on how to replace windows the right way.

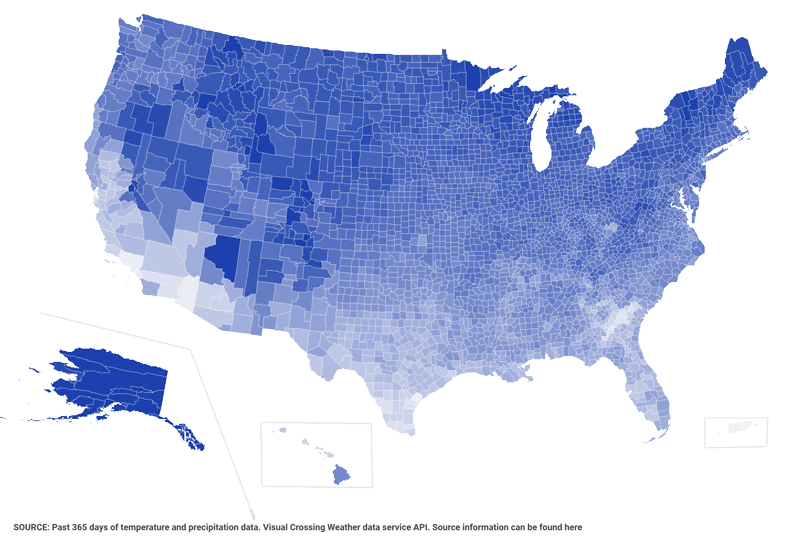

HOW WEATHER AFFECTS YOUR WRB INSTALLATION

Many traditional air barriers can only be applied in dry conditions and with temperatures above 40°F. That can equal significant delays in construction timelines. That's why we specifically formulated R-Guard air and water barriers for easy installation even in damp and cold conditions.

How many days would your project be delayed by the weather? Take a look at our weather data tool to dive into these weather effects by region, county, and city.

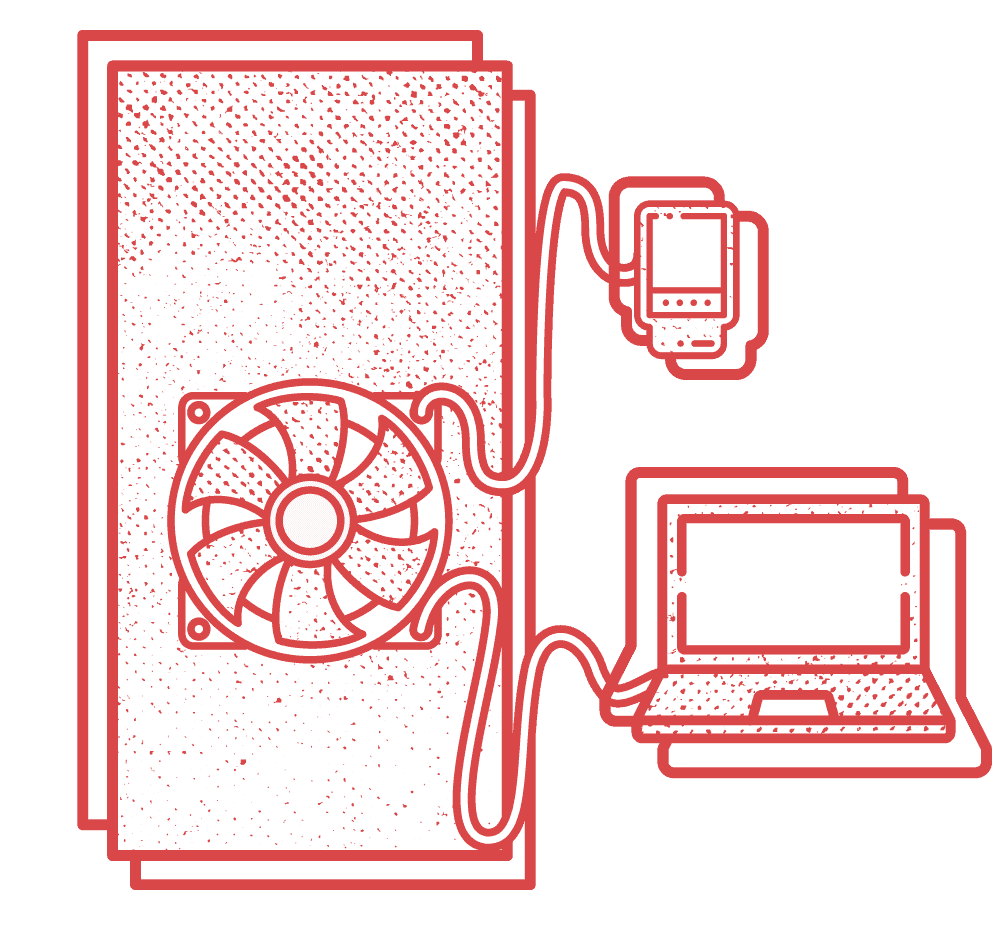

PROSOCO's

Guide to Blower Door Testing

Everything you need to know about blower door tests, including expert advice on how to pass one, how and when to conduct one, success stories and more.